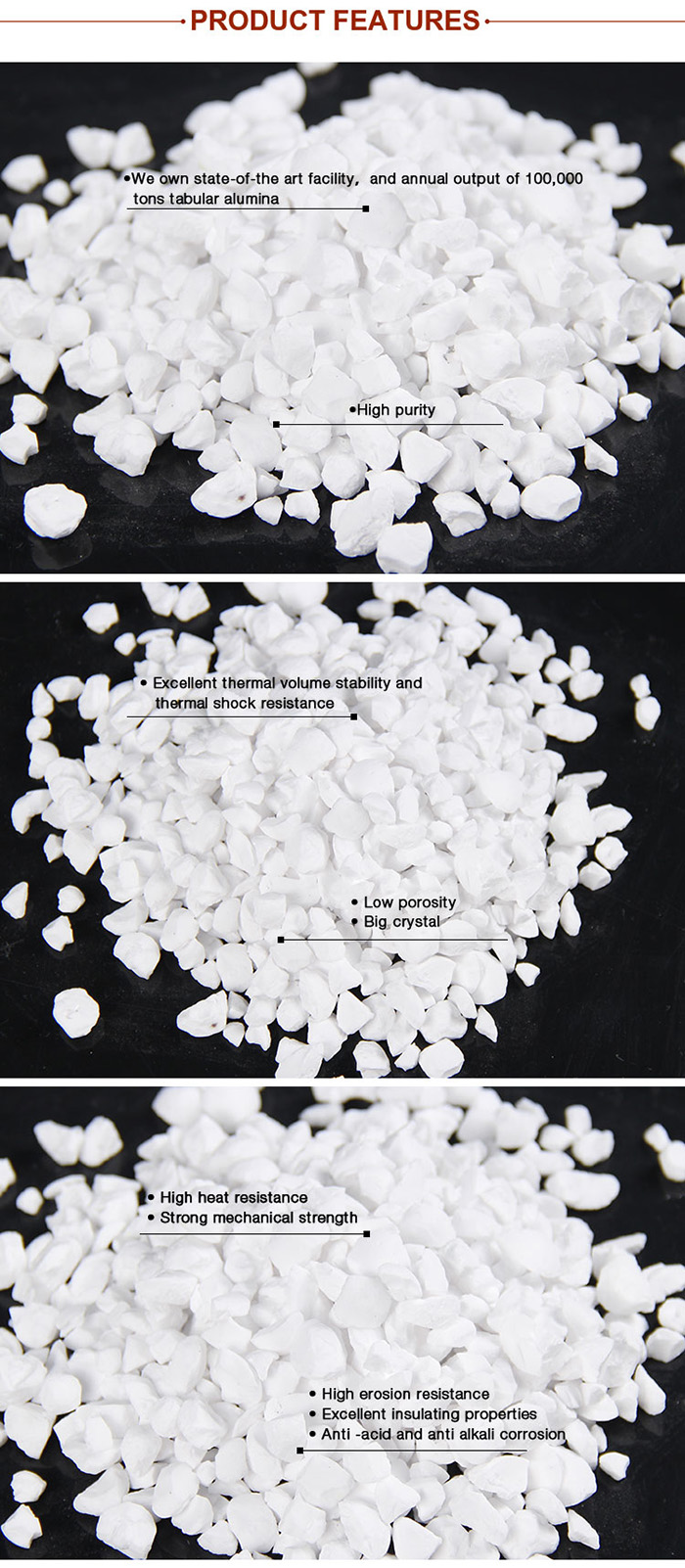

Tabular Alumina is the alumina sintered at ultra-high tempurature. It has a thick and well-developed crystalapha- phase

Al2O3 structure, which is sheet- like in microcosmic. The content of Al2O3 in Tabular alumina is over 99%. It has low

apparent porosity and water absorption, high purity, good volume stability, and very small reburning shrinkage. It can be

used to produce refractories or castables, which has excellent thermal shock stability, scour resistance and flexural strengthafter

high temperature treatment.

Application

1. Refractory bricks, refractory ceramics, etc.;

2. Ceramic deburring, surface treatment, etc.;

3. Wear-resistant coatings, fire-resistant coatings, wear-resistant machinery, etc.;

4. Smelting, casting, steel mills, power plants, etc.;

5. Refractory materials, furnace charges, aggregates, castables, ramming materials, plastics, holding materials, projecting materials,

spray coatings, vibrating materials, refractory slurries, etc.

Characteristics

High refractoriness, high corrosion resistance, high slag resistance, high thermal shock resistance, high strength, good toughness

and chemical stability, high erosion resistance.

Brands

Al2O3%≥

Bulk Density g/cm3≥

Apparent Porosity%≤

Diamter mm

Water Absorption

SiO2%

≤

Fe2O3%≤

Na2O%

≤

AT-1

99.2

3.50

3

spherical beads

1

0.01

0.005

0.35

AT-2

99.2

3.50

3

0-0.3

0-1

1-3

3-6

5-10

1

0.01

0.005

0.35

AT-3

99.2

3.50

3

200mesh

300mesh

1

0.01

0.005

0.35

Name: Tony Wang

Mobile:0086-18753244455

Tel:0086-18753244455

Whatsapp:0086 18753244455

Email:tony@leadsunrefractory.com

Add:No. 718, Qingshan Road, Licang District, Qingdao, China

We chat