|

Item |

SK-30 |

SK-32 |

SK-34 |

SK-36 |

SK-38 |

|

AL2O3 % (min) |

30-35% |

35-38% |

38-42% |

50-55% |

60-65% |

|

Fe2O3% (max) |

3 |

3 |

2.8 |

2.5 |

2.3 |

|

Refractoriness |

≥1690°C |

≥1710°C |

≥1750°C |

≥1770°C |

|

|

Refractoriness under load, 0.2MPa, (°C) |

≥1270°C |

≥1350°C |

≥1350°C |

≥1430°C |

≥1450°C |

|

Apparent porosity (%) |

20-24 |

20-24 |

19-23 |

18-22 |

18-22 |

|

Bulk density (g/cm³) |

2.00-2.05 |

2.05-2.1 |

2.1-2.15 |

2.15-2.25 |

2.25-2.35 |

|

Cold crushing strength (MPa) |

≥25 |

≥30 |

≥35 |

≥45 |

≥50 |

|

Thermal expansion at 1000°C (%) |

≤0.6 |

≤0.55 |

≤0.55 |

≤0.4 |

≤0.4 |

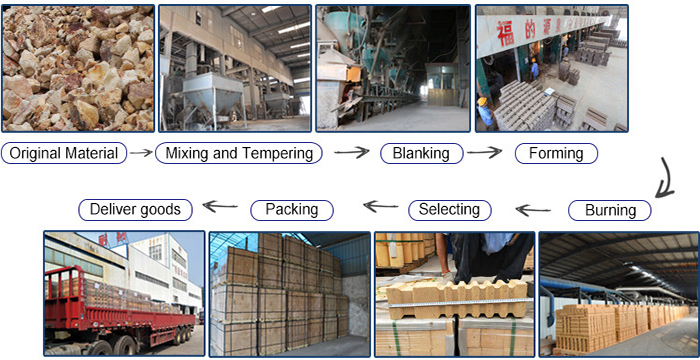

Leadsun Refractory produce a comprehensive range of Fire clay brick consisting of 30-55% Alumina all of which exhibit excellent strength.For more arduous environments we offer a hand fired “super duty” Fire clay brick with a very high mechanical strength.

Typically our firebrick range is based upon flint clay giving it both a low iron and low alkali characteristic.Resistance to thermal shock,abrasion,chemical attack and reducing atmospheres are just some of the key criteria determining choice of product within each application.a wide range of sizes are held in stock.

1.low thermal conductivity, good thermal insulation performance.

2.long service life, easy operation, could be shaped freely

3.Product specification: standard form, normal standard, shaped and special shaped bricks.

4.Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Name: Tony Wang

Mobile:0086-18753244455

Tel:0086-18753244455

Whatsapp:0086 18753244455

Email:tony@leadsunrefractory.com

Add:No. 718, Qingshan Road, Licang District, Qingdao, China

We chat